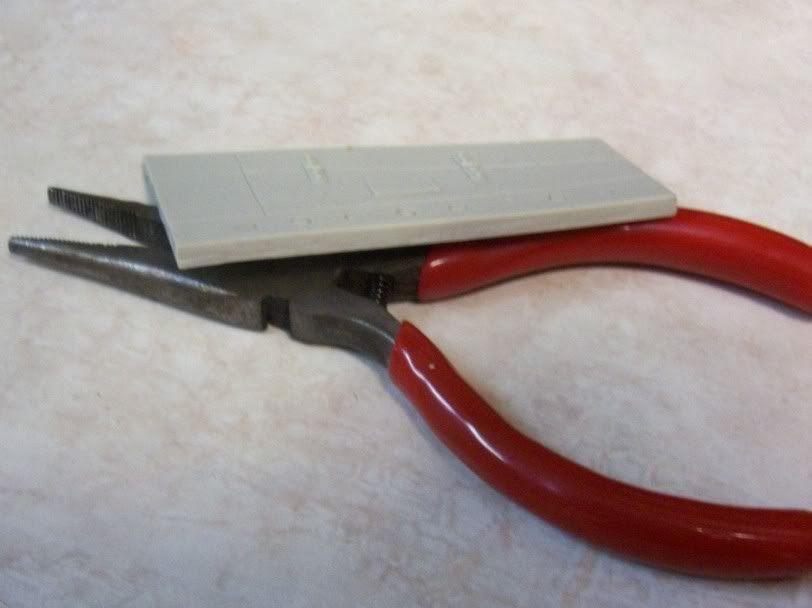

The idea is that many times there is excess room in, for example, a ball and socket joint that makes the point of contact for the glue on the surfaces very low. When you put something in there to soak up the empty space, you get a more solid join. Here is how I do it.

In the picture below you can see the Retribution Invictor is ready for his arms. The arms are ready and two tiny pieces of paper towel material are nearby. The paper towel was cut from a blue design to show up better in the pictures.

Next, I put a very tiny amount of super glue into the receiving side of the joint, in this case the main body of the mini. Then I use the tip of an exacto knife to pick up the tiny pieces of paper towel and place them into the joint. You don't want to put so much glue in there that they become soaked. Once soaked the paper towel hardens pretty darn quick and we want it to stay soft and pliable at this stage.

For the final step I put a generous amount of super glue on the remaining part to be joined, in this case the arms. When I place the arms in the sockets the paper towel will soak up the excess glue and conform to both halves of the join. So instead of arms that are glued on, but only touching in some areas of the join, I now have arms that are solidly glued to paper towel (which is hard as a rock now) and paper towel that is solidly glued to the rest of the mini.

I don't know how many people know this tip already, but if I help just one person prevent the arms of their tiny warriors from falling off, then I've done my job! As always, feel free to let me know what you think. I'm always keen to hear from you folks out on the inter-web!